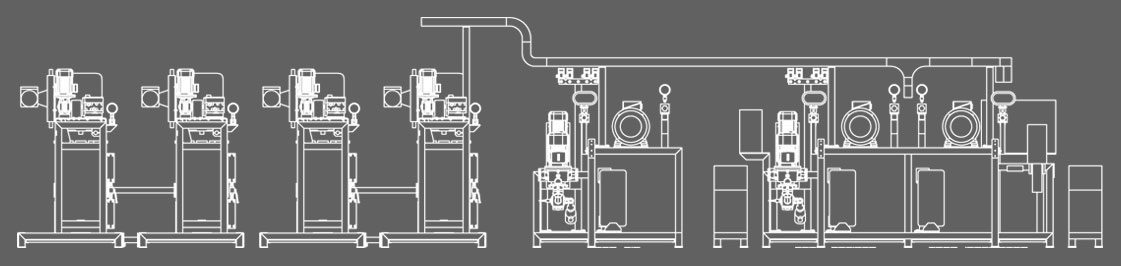

Foaming machines

Foaming machines have the task to measure out, thermal-regularize and pressurize all the liquid or gaseous materials for the creation of the polyurethane foam and the polyurethane glue.

The foaming equiment is composed by:

» Mixing and multicomponents dosing units in high pressure for PUR or PIR insulating foam. The dosing unit provides the control of flow rate and temperature of all the chemical components;

» Pentane metering unit used for the control of the blowing agent flow rate in the polyurethane foam;

» High pressure air nucleator to inject high-pressure air;

» Supply bar with high pressure mixing head: distribution of foam by oscillatory movements with precise control of position and speed of head, or distribution by fixed beam.

Multi components foaming machine

Provides the control of all the chemical components.

Pre-machine tanks

Tanks for the chemical components used for the polyurethane foam.

Catalists tanks

Tanks for the chemical components that trigger the polyurethane foam creation.

Pentane metering unit

Controls the flow rate of the blowing agent.

Foaming beam

Distribution of the polyurethane foam on the metal sheet.

Primer

Adhesive mixture dosing unit.

Primer crossbar

Distribution of the adhesive mixture.